Plastic Mold

8 cav mould with Material change for Plastic Tube out

Plastic PP or TPU , the tool design must consider the different shrinkage value between the 2 material

Description

Reviews

Specifications

Part name : tube out , 30*10*15mm

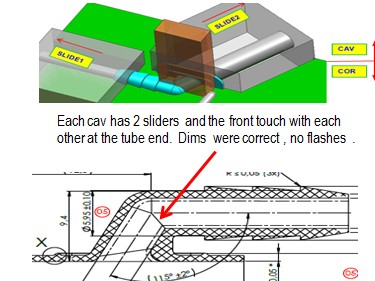

It is the inner component of hearing device. Most of the dims with tolerance +/-0.05mm but customer required use 2 material for production. The white one is PP while the bule one is TPU . Therefore the tool design must consider the different shrinkage value between the 2 material. used H13(1.2344) steel for Cavity and core blockes and S7(1.2767) steel for sliders. Each cav has 2 sliders and the front touch with each other at the tube end. Dims were correct , no flashes

Product Description

Advantages of our Plastic injection

1. Short lead-time, normally 3-6 weeks depends on part size and complexity.

2. High Quality steel with proper heat treatment to Ensure long lifetime .

3. we supply "one-stop" service include molds making, injection, painting, screen printing, assembly and after-sales service

4. Full set of machines inhouse for mold making and injection molding.inlclude Sodick high speed CNC center, Charmilles

high precision Mirror EDM machines, Hexagon CMM with measuring range 1000*800*600mm

5. DFM,Moldflow,part optimization or modification .predeformation analysis. all in 1-3 days

6. Part Analyse & Optimization and Mold design processed by Engineers with 6 or more years experienced in the industry.

7. Mould's steel as per customers' requests such as 2083,2344, 8407,NAK80, S136(H),2738, 718, 738 and etc.

8. Final products' materials' optional:POM,PVC, ABS, PP, PE, POM, PA6(66)+GF, PC, PMMA, HIPS, GPPS and etc.

9. Products' color: Pantone or RAL standards or acording to customer,s color plate & sample

10. All dims in tolerance according to the 2D drawing from customer

11. European and American standard for project management and Quality control

12.Provide progress report ,measurement report and certificates weekly In office format

13. Good cost performance and high effeciency of respond & delivery.

Our Services

1. All inquiry will be replied within 6 hours in working day.

2. Well trained and experienced staffs will answer customer's question in flent English.

3. Competetive prices base on most reasonable managemnt system ,high quality and service.

4. We have an team with rich experience of project manager, design engineers and technicians.

5. We will give best mould solution based on customer's request and part design

6. Before start to build mould,we will supply mould drawing in stp or X_T format to customer for approve.

7. All mould supply sustainable spare parts ,user manual, final mould 2D,3D drawing.

Share your thoughts

Showing

6

of

0

reviews

Most recent

Top Reviews

Read more

Your rating

Your review *

Name *

Enter your Name

Email *

Enter your Email

Submit

Contact Us Now

Enter your inquiry details, We will reply you in 24 hours.

Name can't be empty

E-mail can't be empty

Company can't be empty

Phone can't be empty

Phone

Products can't be empty

Products you want

Message can't be empty

Verification code error

Refill

People who viewed this item also viewed