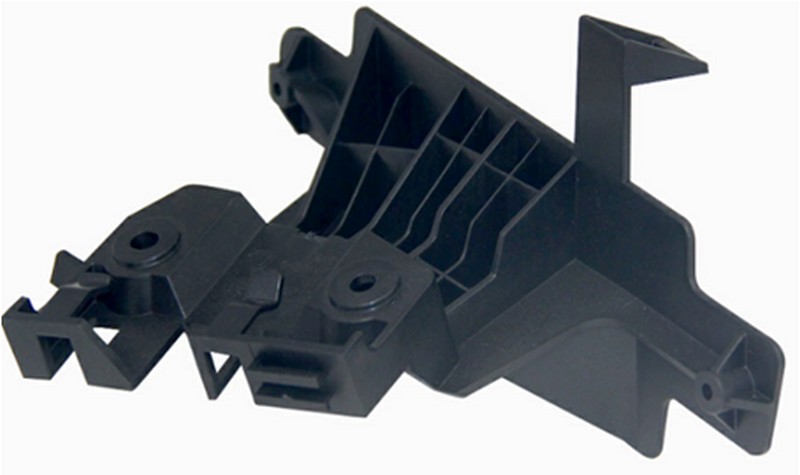

Plastic Mold

Support Frame Bracket

For end customer Lear BMW

Description

Reviews

Specifications

Automotive mold

PA66 GF30 material require high hard steel

Product Description

Advantages of our auto car parts injection

We have a professional tooling design team with several years experience.

1. Various materials and short lead-time

2. Good steel and long lifetime .

3. We can supply "one-stop" service with molds opening, injection, painting, screen printing, assembly and nice after-sales service in long term

4. Full set of machines for mold making and injection molding

5. OEM&ODM service available

6. Mould's design based on tooling engineer from our company and experienced with years in the dustry.

7. Mould's steel as per customers' requests such as NAK80, S1369(H),2738, 718, 738 and etc.

8. Final products' materials' optional: ABS, PP, PE, POM, PA6(66)+GF, PC, PMMA, HIPS, GPPS and etc.

9. Products' color: As the customer's requirments, any color is possible, if they could provide us the color card schedule.

10. Relevant requirements reachable: RoHS, UL, or as the request.

11. Certifications Authorized: ISO9001&ISO14001 Certificated.

12. Japanese standard of QC management and Euramerican standard of checking.

13. Service scope: Open mould, Injection, CNC processing, coating, screen printing, assembly for finished products and so on.

14. Good cost and high effeciency of delivery.

Our Services

1. All inquiry will be replied within one working day.

2. Well trained and experienced staffs will answer customer's question in flent English.

3. Competetive prices base on high quality and service.

4. We have an team with rich experience of project manager, designers engineers and technicians.

5. We will give best mould solution based on customer's request.

6. Before start to make mould,we will supply mould drawing in stp or X_T format to customer for approve.

7. All mould supply sustainable spare parts ,user manual, CD disk with mould 2D,3D drawing.

Share your thoughts

Showing

6

of

0

reviews

Most recent

Top Reviews

Read more

Your rating

Your review *

Name *

Enter your Name

Email *

Enter your Email

Submit

Contact Us Now

Enter your inquiry details, We will reply you in 24 hours.

Name can't be empty

E-mail can't be empty

Company can't be empty

Phone can't be empty

Phone

Products can't be empty

Products you want

Message can't be empty

Verification code error

Refill

People who viewed this item also viewed